New trends of traditional papermaking in Lijiang

Editor's note: In Lijiang old town, the brothers of He Xiuhong, He Xiujun and He Xiuchang are master hands in traditional Dongba papermaking. Over the years, the Naxi brothers have been running Handicraft of Lijiang -- a Dongba papermaking mill -- by fusing tourist activities into the intangible cultural heritage. They rolled out the weeklong papermaking courses and month-long Dongba paper tours for teenagers and pupils, and the experience-based activities in papermaking drew streams of visitors.

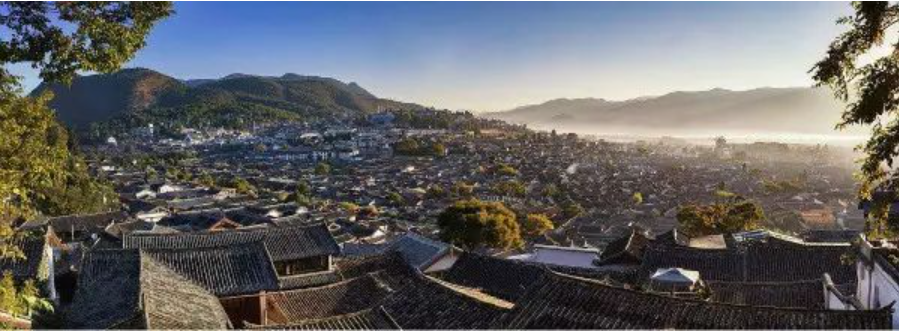

An overview of the Lijiang old town (Online photo subject to deletion)

New trends of traditional papermaking in Lijiang

In northwest Yunnan’s Lijiang old town, there sits Handicraft of Lijiang -- a traditional Dongba papermaking mill. Here, the repeated papermaking inheritance, the bark-gathering and the new skills in blanketing all contributed to the fascination of the Naxi-styled courtyard.

The Dongba paper is a cultural medium of the Naxi ethnic group. The Handicraft of Lijiang papermaking mill was jointly established by the brothers of He Xiuhong, He Xiujun and He Xiuchang. As a brand new tourist project that infuses culture deep into tourism, the Dongba papermaking mill has invited in numerous tourists in recent years.

Every week, the three brothers and their family members would spend three or four days making the Dongba paper. The brothers are both craftsmen and presenters. “The paper is special in that it can remain intact for centuries, be water proof and endure high temperature,” said He Xiuhong. Without the resilience of Dongba paper, He added, the Dongba characters of Naxi people couldn’t have been preserved till today.

In each step of the Dongba papermaking, the three brothers still strictly follow the repeated instructions from their father He Ziqiang. Born in 1926, the father picked up papermaking in 1938, and has devoted himself to the Dongba papermaking and its cultural inheritance.

A street in the Lijiang tourist town (Online photo subject to deletion)

Influenced by what they constantly heard and saw from the father He Ziqiang, the brothers have learnt the papermaking skills by heart since childhood. Over the past decades, the three brothers have never thought of giving up the trade however hard it was. “If we hadn’t insisted on it, the papermaking craft could have disappeared,” said He Xiuhong.

As of now, the brothers have developed tourist products that combine the Dongba paper with embroidery, carving, calligraphy and painting. In January 2018, they rolled out Dongba papermaking programs, including the hour-long experience course, the weeklong papermaking skills and the month-long Dongba paper tours. Since then, the experience-based activities in papermaking have drawn streams of visitors. He Xiuhong said around 20 pupils spent one month on Dongba papermaking during the summer vacation that year.

The in-depth experiencing programs begin with gathering canescent wikstroemia, a special material for Dongba papermaking. The plant contains a slight toxin that inhibits the growth of bugs and makes the Dongba paper more resilient.

The collected wikstroemia bark needs to be boiled for a whole day. “Fire ash needs to be added into the boiled water, or the bark will never get soft,” said He Xiuchang, piling up some boiled bark pieces for further sorting and clearing.

The shop sign of Handicraft of Lijiang -- a Dongba papermaking mill (Online photo subject to deletion)

The clearing is a complicated manual processing that will define the clearance of the final paper pieces. In sorting the bark pieces, the craftsmen need to carefully tear down the coarse or rotten parts of the bark in three rounds. Whenever the family members had time, they would set down to clear the wikstroemia skin. Before that, the daily portion had been soaked in water overnight. “The soaked portion of the bark pieces needs to be sorted out in the same day, or they will be useless on the next day,” said He Xiuchang.

Then the cleared bark will be boiled for another week before it is taken out and cut up. After the bark bits are evenly pounded with water in a mortar, the fermentation begins. When we saw He Xiuchang, he was pounding the bark. “A slight mistake is to be made up for by multiple efforts,” said He Xiuchang. He told us the proceedings are so complicated that even a senior paper maker like him -- with a 20-year experience in the trade -- makes mistakes at times.

The fermentation usually lasts for one month, with water replenished every ten days. The fermented mixture liquid can be taken out to form paper pieces. Every day, He Xiuchang can at most produce 30 pieces with the size of 30*60cm. If it is for the 95*135cm Dongba paper, only three or four pieces can be blanketed out by two brothers. Though two hands are needed, the success rate only stands at 50 percent.

These days, He Xiuhong is trying to put together woodblock painting, wax printing and Dongba paper, in a bid to use other heritages to better spread the Naxi heritage. While striving for developing the Dongba paper cultural products, He also tried to teach the craft in local schools. “I hope the Naxi handicraft of traditional papermaking can be passed down to future generations,” said Xiuhong.

Reporting by Gong Jingyang; Trans-editing by Wang Shixue